Upon adding an extra lock to the Workshop’s door, I decided that I must cover the hole to protect it from the rain. At first, I thought about using parts and doing some constructive cutting. To get the best out of it, fabricating one from a 3D model, would be best…and unique.

Knowing that I needed a plate of sorts, I began with that and added the extras by extruding from the faces. I was able to cut the main hole out by using a cylinder and extracting it. If you are clued up about 3D Modelling, then this is quite a simple job and well within my limited abilities. I also wanted to sign it, so what was better than ‘TSE.’

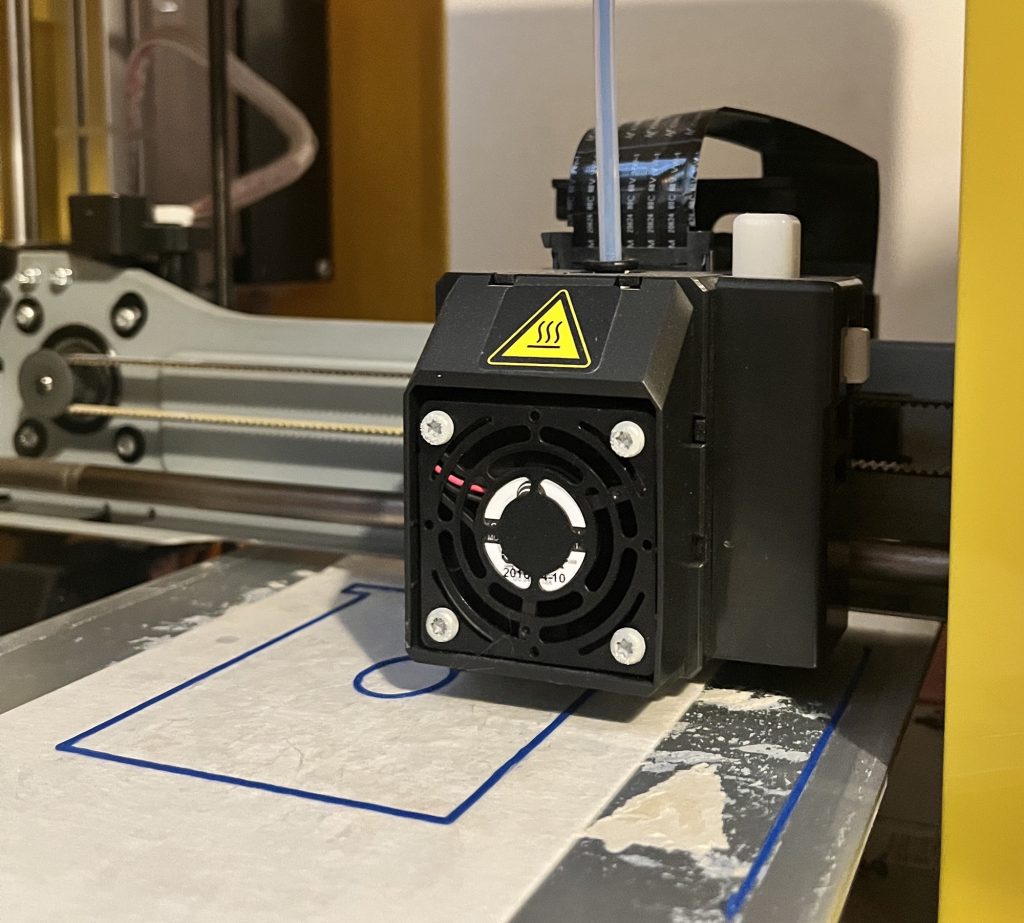

To summarise, I was given a challenge with moving it to my slicing software. I had to resize it as best as I could. Using a program like Blender is not the best option and it highlighted the need to get on with working in CAD. It works fine, even with the curls on the lower tips, it is serving its purpose. As it is only a toy-like 3D Printer, I am always happy with what is produces. I’m like a child when it’s printing, it still fills me with wonder, thus I deem it one of the best bits of tech to be produced in this century, so far!